Electric Coil

Introduction

Electric coils in air handling units (AHUs) for HVAC systems are electric heating elements that warm incoming or recirculated air to maintain desired indoor temperatures, especially in heating modes or transitional seasons. An electric heating coil (also called an electric heater) is a heating element installed inside an Air Handling Unit (AHU) or duct to raise the temperature of air supplied to conditioned spaces. It converts electrical energy into heat and is commonly used where hot water or steam heating is not available.

Function

These coils heat air passing over them via resistive elements powered by electricity, raising air temperature before distribution through ducts. They provide precise, rapid heating without combustion, ideal for supplemental or primary heating in milder climates.

Purpose of Electric Coil in AHU

- To heat supply air during winter or cold conditions

- To maintain room temperature as per HVAC design

- To provide reheat in VAV or humidity control systems

To serve as a backup or supplementary heat source

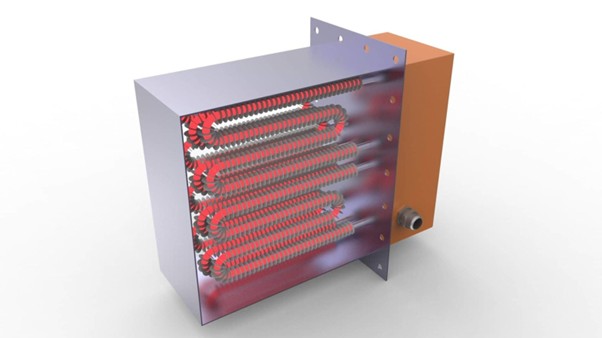

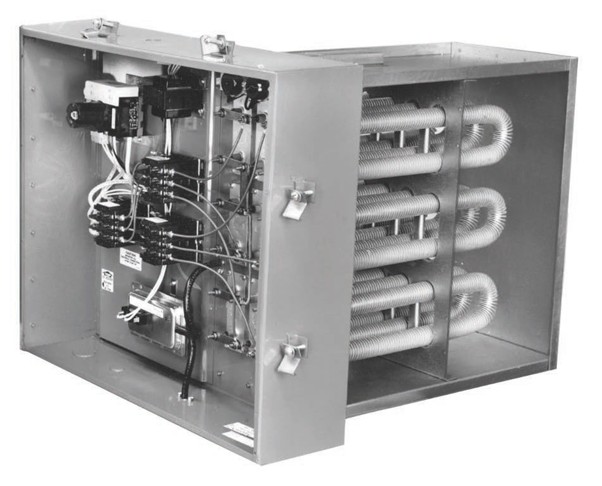

Construction & Components

Electric heating coils typically consist of:

Heating elements: Resistance wire (usually nickel-chromium / nichrome)

Insulators: Ceramic or mica supports

Frame: Galvanized steel or stainless steel

Terminal box: Electrical connections

Safety devices:

- Automatic reset thermal cut-out

- Manual reset high-temperature cut-out

- Airflow switch (optional but recommended)

Design Features

Typically constructed from ni chrome or stainless steel wires wound into coils or fins, encased in galvanized steel casings for durability and corrosion resistance. They feature finned surfaces to maximize heat transfer (up to 80-90% efficiency) and are sized based on airflow (CFM) and temperature rise needs, often 5-12 rows deep with 8-14 fins per inch.

Types

Open coil: Exposed nichrome wires for high-temperature applications (up to 800°F), common in commercial AHUs.

- Exposed heating elements

- Fast heat response

- Used where airflow is clean and controlled

Finned tubular: Sheathed elements with aluminum fins for even heat distribution and easier cleaning.

- Heating element enclosed in metal sheath with fins

- More robust and safer

- Commonly used in commercial AHUs

Duct-Mounted Electric Heaters

- Installed in supply air duct downstream of AHU

- Used for zone reheat applications

Working Principle

When electrical power is supplied, the resistance wire heats up. As air passes over the coil, heat is transferred to the air stream, increasing the supply air temperature before it is delivered to the conditioned space.

Advantages

- Simple installation

- Precise temperature control

- No piping, pumps, or boilers required

- Clean heating (no combustion)

Limitations

- Higher operating cost compared to hot water or steam

- Requires adequate electrical capacity

- Strict safety interlocks needed to avoid overheating

Typical Applications

- Commercial buildings

- Hospitals and laboratories

- Clean rooms

- Data centers (reheat applications)

- Residential and light industrial HVAC systems

Typical Technical Parameters

- Voltage: 230 V / 415 V / 480 V

- Power rating: 3 kW to 100+ kW

- Control: ON/OFF, step control, SCR/thyristor

- Air velocity: Minimum airflow required to avoid overheating

- Temperature rise: As per HVAC design

Safety & Standards

- Must be interlocked with AHU fan operation

- Overheat protection mandatory

- Designed as per IEC / UL / IS standards

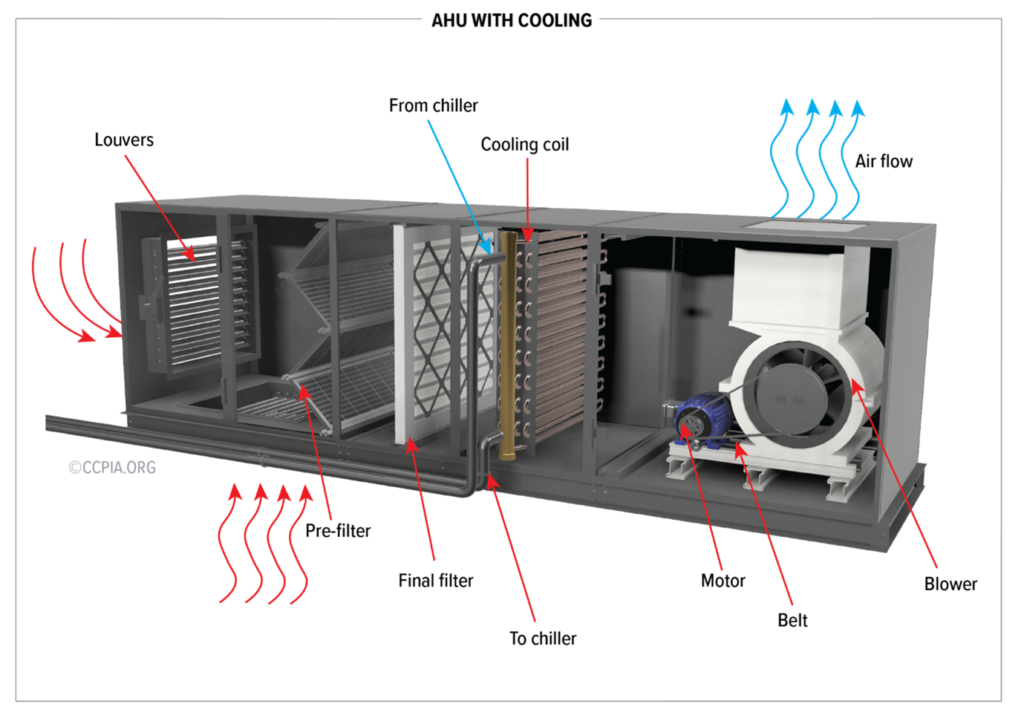

Installation and Operation

Positioned downstream of filters and fans, upstream of cooling coils in multi-coil AHUs. Controlled by thermostats or building management systems (BMS) with SCR (silicon-controlled rectifier) for modulation, preventing temperature overshoot. Power ratings range from 5-50 kW per unit, drawing 3-phase electricity.

Maintenance Tips

Clean fins quarterly to avoid dust buildup reducing efficiency; inspect for hotspots or insulation damage annually.