Rotary Heat Exchanger

Introduction

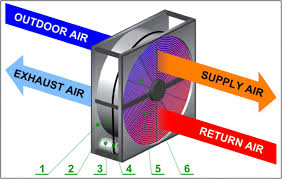

A Rotary Heat Exchanger, also called a Heat Wheel or Enthalpy Wheel, is a rotating cylindrical wheel installed between:

· Fresh (outdoor) air stream

· Exhaust (return) air stream

It recovers

A Rotary Heat Exchanger, also called a Heat Wheel or Enthalpy Wheel, is a rotating cylindrical wheel installed between:

- Fresh (outdoor) air stream

- Exhaust (return) air stream

It recovers energy from exhaust air and transfers it to incoming fresh air — reducing HVAC load and energy cost.

Rotary heat exchangers, also known as thermal wheels or enthalpy wheels, are key components in air handling units (AHUs) for HVAC systems. They recover heat and sometimes moisture between exhaust and incoming air streams to boost energy efficiency. energy from exhaust air and transfers it to incoming fresh air — reducing HVAC load and energy cost.

Rotary heat exchangers, also known as thermal wheels or enthalpy wheels, are key components in air handling units (AHUs) for HVAC systems. They recover heat and sometimes moisture between exhaust and incoming air streams to boost energy efficiency.

Working

- The wheel rotates slowly (10–20 RPM).

- One half of the wheel passes through exhaust air:

- Absorbs heat (and moisture).

- The other half passes through fresh air:

- Releases stored heat (and moisture).

- Cycle repeats continuously.

Result: Pre-heated air in winter / pre-cooled air in summer.

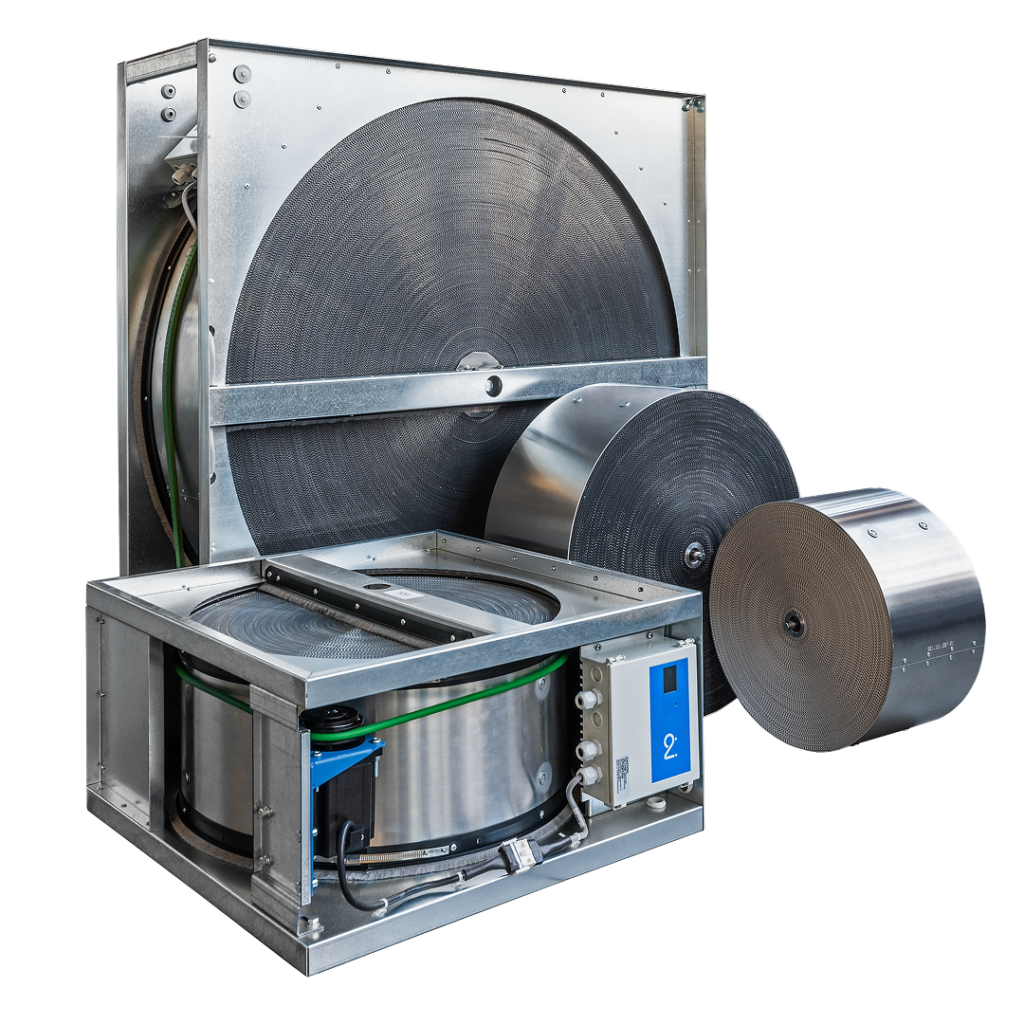

A rotating wheel filled with aluminum foil or a desiccant matrix alternate between warm exhaust air and cold supply air. This setup transfers sensible heat (temperature) and, in enthalpy wheels, latent heat (moisture), achieving up to 85% efficiency in ideal conditions. The wheel spins slowly, typically 5-20 RPM, to avoid airflow mixing while maximizing transfer.

Type of Rotary Heat Exchanger

- Sensible Heat Wheel

- Transfers only temperature

- Made of aluminum

- No moisture transfer

- Used where humidity control is critical

- Enthalpy (Total Heat) Wheel

- Transfers temperature + moisture

- Special hygroscopic coating

- Most common in comfort HVAC

Performance

Typical efficiencies:

- Sensible efficiency: 70–85%

- Latent efficiency: 60–75%

- Overall energy recovery: up to 80%

This is much higher than plate heat exchangers.

Limitations / Concerns

- Cross contamination risk

- Exhaust air can leak into fresh air

- Not ideal for hospitals, labs (unless purge section added)

- Requires motor, belt, seals → maintenance

- Higher initial cost

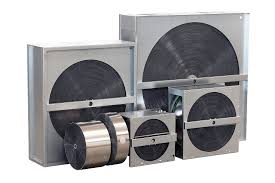

Key components

- Rotor matrix (aluminum/hygroscopic)

- Drive motor & belt

- Bearings

- Purge sector (optional)

- Seals

- Control system (VFD or on/off)

Control & operation

- Controlled by:

- Temperature sensors

- Humidity sensors

- BMS

- Wheel speed adjusted via VFD

- Can be bypassed using dampers when not needed

Rotary Vs Plate Heat Exchanger

Feature | Rotary | Plate |

Efficiency | More than Plate Heat Exchanger | Lesser |

Moisture transfer | Yes (enthalpy) | No |

Moving parts | Yes | No |

Cross-contamination | Possible | None |

Size | Compact | Larger |

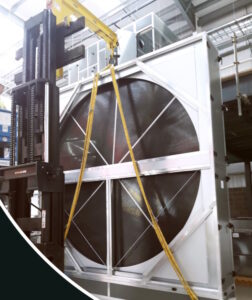

Common Applications

- Commercial buildings

- Malls

- Airports

- Offices

- Data centers (with sensible wheels)

- Industrial AHUs